-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

The production process of N,N-dimethyl 3-nitrobenzenesulfonamide (DNB) involves several steps, which can vary depending on the scale of production and the desired purity of the final product.

The following is a general overview of the production process of DNB in the chemical industry.

- Raw Material Preparation

The production of DNB begins with the preparation of the raw materials, which include dimethyl sulfate, benzene, and nitric acid.

Dimethyl sulfate is prepared by the reaction of methyl chloride and sulfuric acid, while benzene is derived from the distillation of coal tar or from the hydration of benzene.

Nitric acid is prepared by the combination of nitric oxide and oxygen or sulfuric acid. - Diazotization

The next step in the production of DNB is diazotization, which involves the conversion of benzene to benzenediazonium salt.

This is achieved by adding nitric acid to benzene in the presence of a solvent, such as water or acetonitrile.

The reaction is exothermic, and it is important to control the temperature to avoid excessive heating. - Coupling

After diazotization, the benzenediazonium salt is coupled with the dimethyl sulfate in the presence of a coupling agent, such as sodium hydroxide or hydrazine.

The reaction is highly exothermic and is usually carried out in a batch reactor or a continuous process. - Purification

After the coupling reaction, the mixture is purified by techniques such as filtration, distillation, and crystallization.

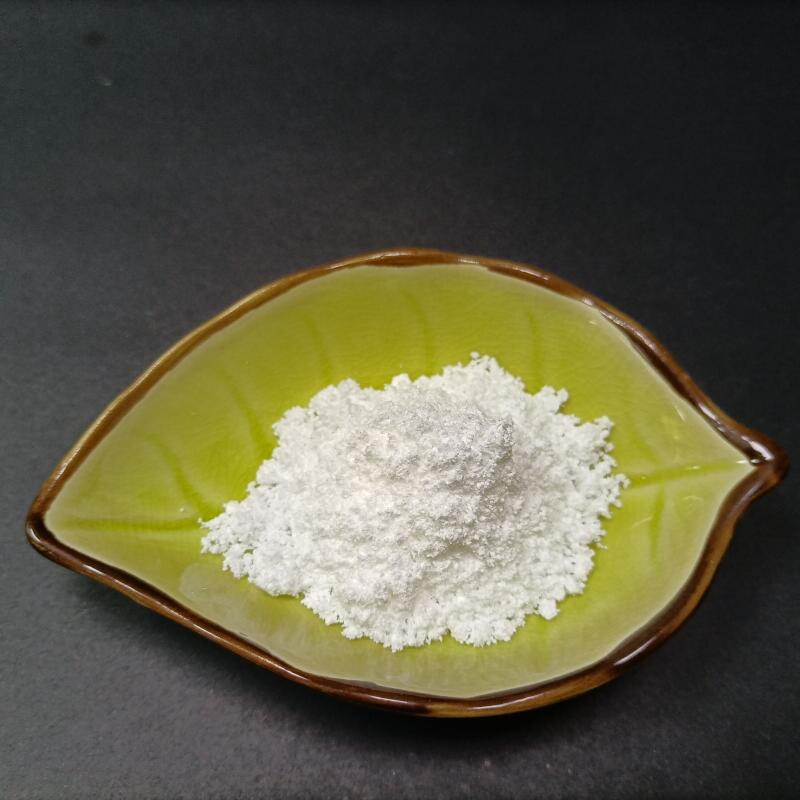

The purified DNB is then dried and packaged for storage and transport. - Characterization

The purified DNB is characterized by different techniques, such as spectroscopy, chromatography, and mass spectrometry, to determine its chemical properties and purity.

The physical and chemical properties of DNB, such as its melting point, boiling point, solubility, and stability, are also determined during this step. - Applications

N,N-dimethyl 3-nitrobenzenesulfonamide has a wide range of applications in the chemical industry.

It is used as a building block in the synthesis of dyes, pharmaceuticals, pesticides, and other chemical products.

It is also used as an intermediate in the production of explosives, plastics, and other industrial chemicals.

In conclusion, the production process of N,N-dimethyl 3-nitrobenzenesulfonamide involves several steps, which require careful control and monitoring to ensure the quality and purity of the final product.

The purified DNB is widely used in the chemical industry as a building block for the synthesis of various chemical products.

It is important to note that the production process and the purity of the final product may vary depending on the specific application and the requirements of the end user.