-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Introduction:

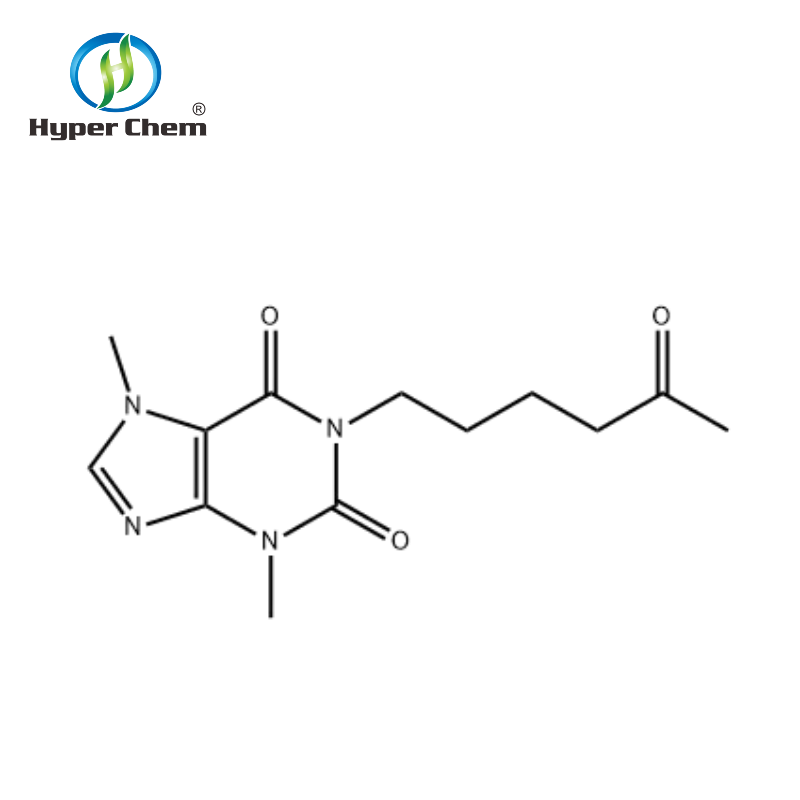

Naftopidil is a pyrazole-based anti-androgen drug used in the treatment of prostate cancer.

The drug is synthesized through a multi-step chemical reaction process that involves several intermediates.

In this article, we will discuss the production process of Naftopidil in detail.

The article will cover the raw material preparation, the synthesis of the intermediate products, and the final steps involved in the production of the finished drug product.

Raw Material Preparation:

The production of Naftopidil involves several raw materials, including p-toluidine, hydroxylamine, and sodium hydroxide.

The raw materials are first procured and then dissolved in water to form a solution.

The solution is then filtered to remove any impurities and the pH is adjusted to a suitable value using hydrochloric acid or sodium hydroxide.

Synthesis of Intermediate Products:

The synthesis of Naftopidil requires several intermediate products, including tryptamine, benzaldehyde, and benzylamine.

Tryptamine is synthesized by the reaction of p-toluidine with ammonia in the presence of a catalyst such as hydrochloric acid.

The reaction produces tryptophan, which is then hydrolyzed to form tryptamine.

Benzaldehyde is synthesized through the benzylation of benzene using a solvent such as toluene and an initiator such as sodium hydroxide.

The reaction is carried out at a high temperature, and the resulting product is then distilled to remove any impurities.

Benzylamine is synthesized by the reaction of benzaldehyde with a primary amine such as ammonia or methylamine.

The reaction is carried out in the presence of a base such as sodium hydroxide, and the resulting product is then distilled to remove any impurities.

Synthesis of Naftopidil:

The synthesis of Naftopidil involves several steps, including the synthesis of the intermediate products and the final steps involved in the formation of the drug.

The synthesis of Naftopidil involves the reaction of tryptamine, benzaldehyde, and benzylamine in the presence of a catalyst such as hydrogen chloride.

The reaction produces Naftopidil, which is then purified using a suitable method such as crystallization or chromatography.

Final Steps in Production:

The final step in the production of Naftopidil involves the formation of the finished drug product.

The drug is formulated by combining the purified Naftopidil with a suitable excipient, such as lactose or starch.

The mixture is then compressed into tablets or filled into capsules, depending on the dosage form required.

Conclusion:

The production process of Naftopidil involves several steps, including the synthesis of intermediate products and the final steps involved in the formation of the drug.

The process requires the use of several raw materials and several intermediate products, including tryptamine, benzaldehyde, and benzylamine.

The final step in the production process involves the formation of the finished drug product, which is then packaged and distributed to the market.

Naftopidil is an important drug in the treatment of prostate cancer, and the production process involves a series of complex chemical reactions that require careful control and monitoring to ensure the quality and purity of the final product.