-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Potassium clavulanate is an antibiotic drug used to treat a variety of bacterial infections.

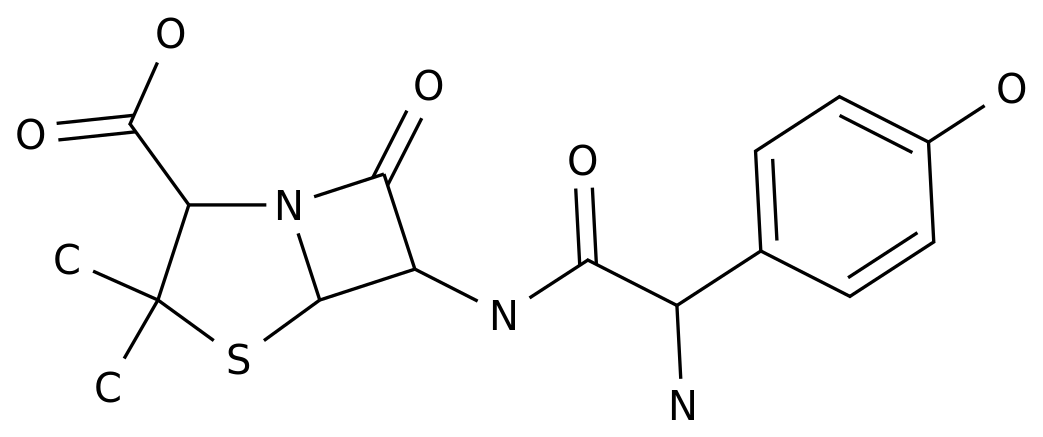

It is a combination of two different drugs, amoxicillin and clavulanic acid, which work together to inhibit the growth of bacteria.

The production process of potassium clavulanate involves several steps, including the preparation of the starting materials, the synthesis of the drug, and the purification and formulation of the final product.

The first step in the production process of potassium clavulanate is the preparation of the starting materials.

This involves the synthesis of amoxicillin and clavulanic acid, which are then combined to form the final drug.

Amoxicillin is a penicillin antibiotic that is derived from a fungus called Penicillium chrysogenum.

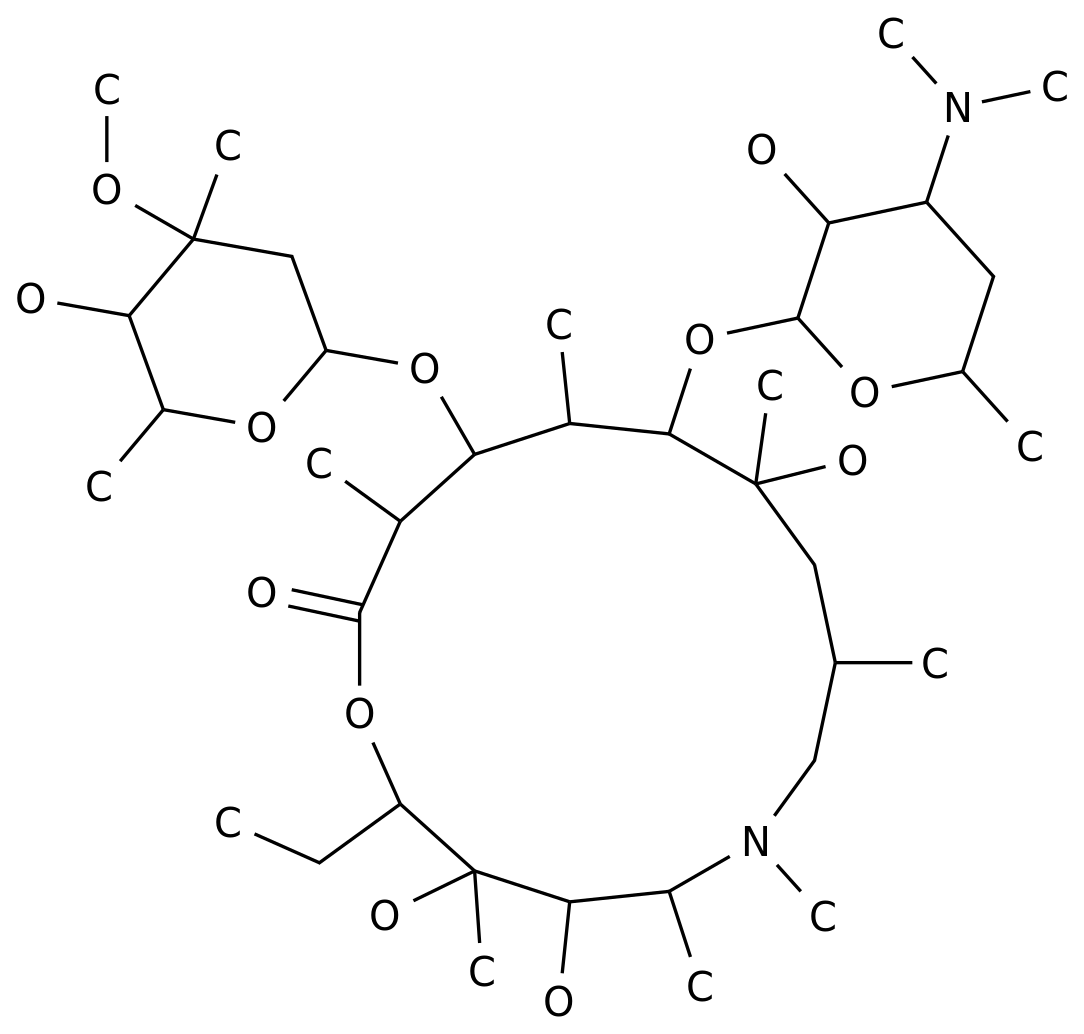

Clavulanic acid, on the other hand, is synthesized from a type of bacteria called Streptomyces clavuligerus.

Once the starting materials have been prepared, the next step is the synthesis of potassium clavulanate.

This involves combining amoxicillin and clavulanic acid in a series of chemical reactions.

The exact details of the synthesis process are proprietary and vary depending on the manufacturer, but the general process involves the use of chemical reagents and catalysts to form the final drug.

After the synthesis of the drug, the next step is the purification and formulation of the final product.

This involves several different processes to remove any impurities and ensure the safety and efficacy of the drug.

The purification process typically involves the use of chromatography and filtration techniques to separate the drug from any unwanted components.

The drug is then formulated into a final product, which may be in the form of a tablet, capsule, or liquid.

The production process of potassium clavulanate is a complex and multi-step process that requires a high degree of technical expertise and equipment.

The drug is typically produced in large quantities by pharmaceutical companies and is available by prescription only.

It is important to follow the dosage instructions provided by a healthcare professional and to avoid any potential side effects.

In conclusion, the production process of potassium clavulanate involves several steps, including the preparation of starting materials, the synthesis of the drug, and the purification and formulation of the final product.

The drug is a combination of two different antibiotics that work together to inhibit the growth of bacteria.

It is produced in large quantities by pharmaceutical companies and is available by prescription only.