-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

- Cosmetic Ingredient

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

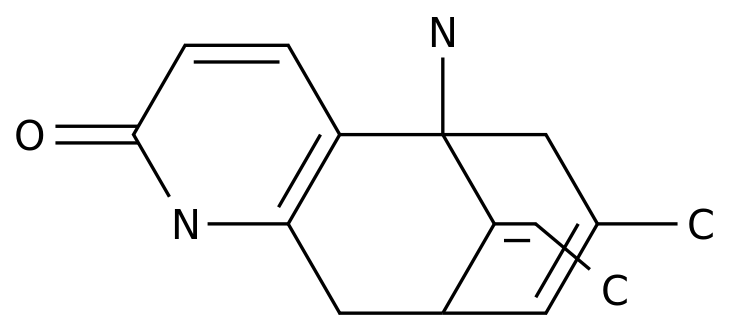

Pramipexole dihydrochloride is a pharmaceutical drug used to treat symptoms of Parkinson's disease and restless legs syndrome.

The production process of pramipexole dihydrochloride involves several steps, including synthesis, purification, and formulation.

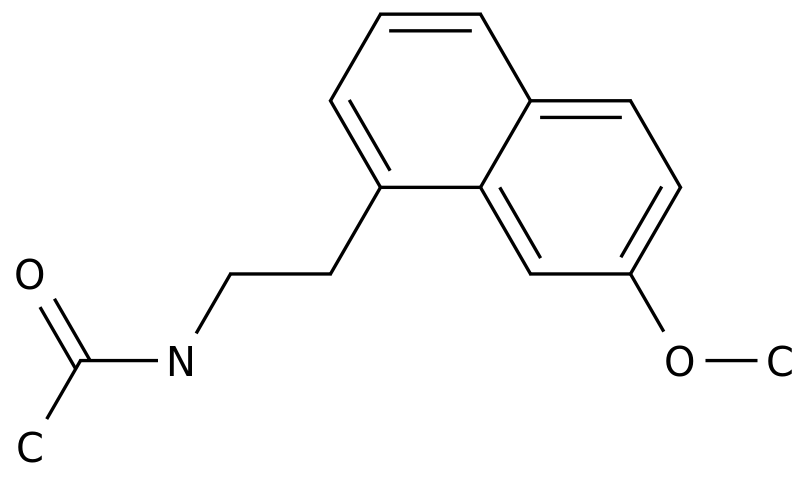

The synthesis of pramipexole dihydrochloride begins with the reaction of a substituted phenethylamine with a suitable reagent such as a halogenating reagent or a reactive derivative of an alcohol.

The reaction product is then treated with hydrazine to yield an N-substituted hydrazide, which is further converted into a salt by treatment with a suitable acid.

The resulting salt is then hydrolyzed to yield the free base of pramipexole dihydrochloride, which is subsequently converted into the dihydrochloride salt.

The synthesis of pramipexole dihydrochloride can be represented by the following equation:

C6H12N2 + X2 + 2NH2OH → C6H12N2X2 + 2NH3 + H2O

where C6H12N2 represents the starting material, X2 represents the halogen or reactive derivative, and NH2OH represents hydrazine.

After the synthesis of pramipexole dihydrochloride is complete, the product must be purified to remove any impurities that may have been introduced during the synthesis process.

This purification process typically involves several steps, including crystallization, chromatography, and recrystallization.

Crystallization is used to separate the desired product from any impurities that may be present.

This is typically done by dissolving the product in a suitable solvent and allowing the solution to cool slowly, allowing the desired crystalline form of the product to form.

Chromatography is a technique used to separate a mixture of chemicals based on their different physical or chemical properties.

In the case of pramipexole dihydrochloride, this technique can be used to separate the product from any impurities that may be present.

Recrystallization is a technique used to improve the purity of a solid material by dissolving it in a suitable solvent and allowing the solution to cool slowly, allowing the desired crystalline form of the product to form.

This process can be repeated multiple times to achieve a high degree of purity.

After the purification process is complete, the pramipexole dihydrochloride is formulated into a final product.

This typically involves mixing the pure product with other materials, such as excipients, to create a final product that is stable and easy to use.

The formulation process of pramipexole dihydrochloride can also involve other steps such as coating, compressing and packaging.

Coating is used to protect the drug from degradation in the stomach and to Control the release of the drug.

Compression is used to shape the dosage form and packaging is used to keep the dosage form safe and stable.

In conclusion, the production process of pramipexole dihydrochloride involves several steps, including synthesis, purification, and formulation.

The process starts with the synthesis of the raw material, followed by the purification process to remove impurities, and finally, the formulation of the final product.

This process is carried out in a controlled environment, such as a pharmaceutical manufacturing facility, and is subject to strict quality control procedures to ensure the safety and efficacy of the final product.