-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

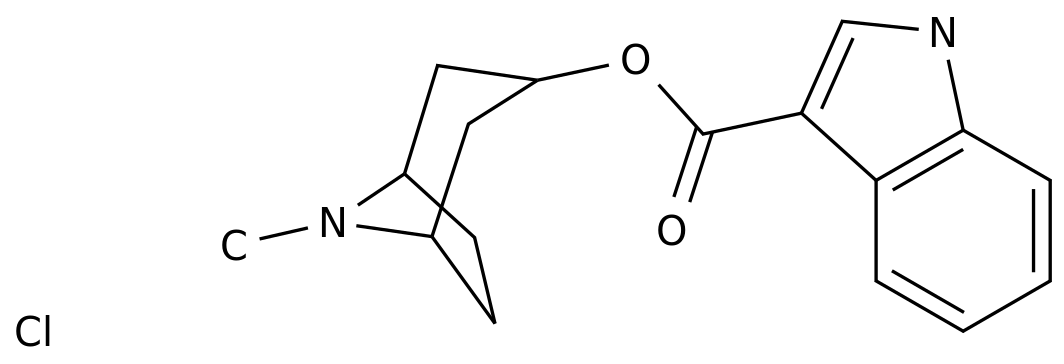

Silodosin is a pharmaceutical drug used to treat the symptoms of benign prostatic hyperplasia (BPH), a condition in which the prostate gland becomes enlarged.

The production process of silodosin involves several steps, including synthesis, purification, and formulation.

- Synthesis: The synthesis of silodosin involves the conversion of a starting material, such as phenylmethylamine, into the desired compound through a series of chemical reactions.

The synthesis process typically involves several steps, including the preparation of intermediate compounds, the coupling of these intermediate compounds to form the final product, and the purification of the product. - Purification: After the synthesis of silodosin, the compound must be purified to remove any impurities that may have been introduced during the synthesis process.

This purification process typically involves a combination of chromatography and crystallization techniques. - Formulation: After the silodosin has been purified, it is formulated into the final dosage form, typically a tablet or capsule.

The formulation process involves combining the pure silodosin with other ingredients, such as excipients, to create a stable and effective drug product. - Quality Control: The production process of silodosin is subject to strict quality control procedures to ensure that the final product meets the required specifications for purity, potency, and stability.

This involves testing the drug at various stages of production, including the synthesis, purification, and formulation stages, to ensure that it meets the required standards.

In conclusion, the production process of silodosin involves several steps, including synthesis, purification, formulation, and quality control.

These steps are essential for ensuring that the final product is safe, effective, and meets all relevant regulatory standards.

The use of advanced techniques and equipment, as well as strict quality control procedures, can help to ensure that the production process is efficient and effective, resulting in a high-quality drug product.