-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Tirofiban hydrochloride monohydrate is a pharmaceutical drug used in the treatment of acute coronary syndrome.

The production process of tirofiban hydrochloride monohydrate involves several steps, including synthesis, purification, and formulation.

Synthesis of Tirofiban Hydrochloride Monohydrate

The synthesis of tirofiban hydrochloride monohydrate involves a multistep process that involves several chemical reactions.

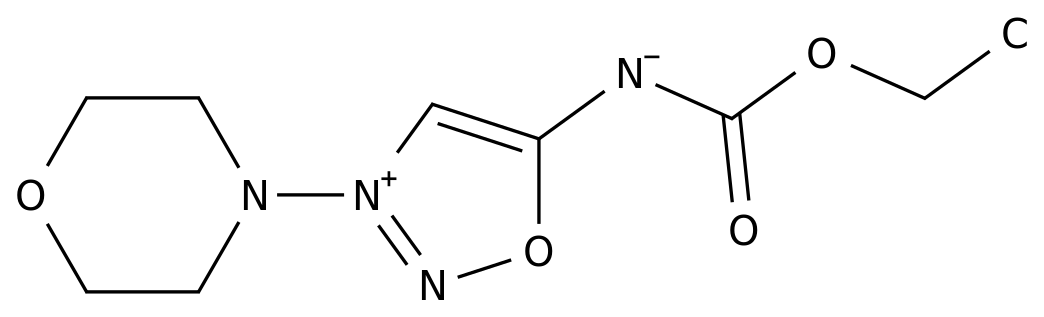

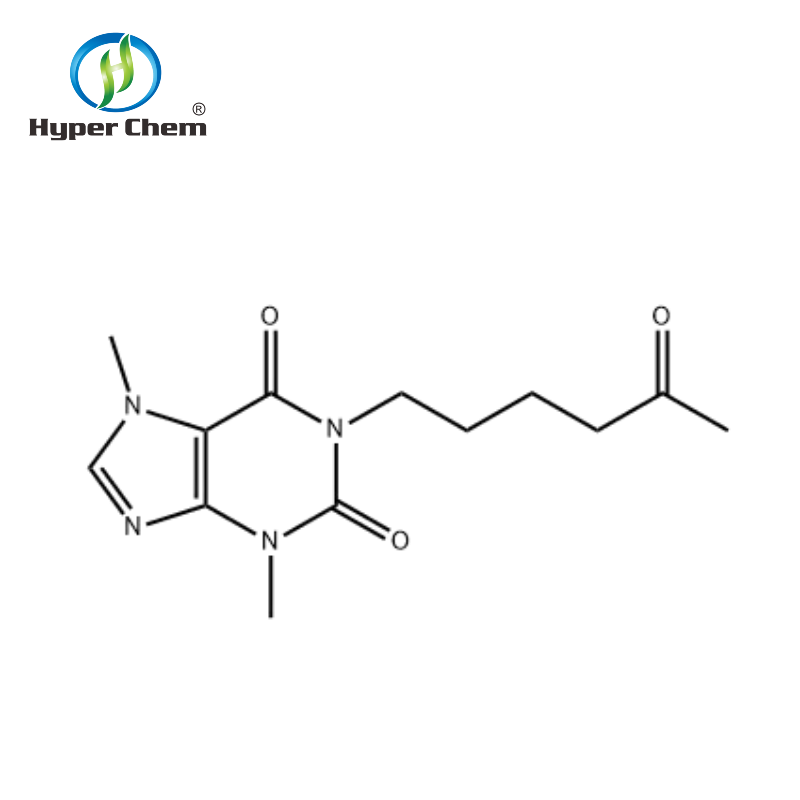

The synthesis process typically starts with the synthesis of the basic structure of the drug, known as a precursor.

The precursor is then modified through a series of chemical reactions to produce the final product, tirofiban hydrochloride monohydrate.

One of the key steps in the synthesis of tirofiban hydrochloride monohydrate is the formation of the lactone ring.

This step involves the reaction of a precursor molecule with a strong acid catalyst.

The reaction produces a lactone ring, which is then transformed into the final product through a series of chemical reactions.

Purification of Tirofiban Hydrochloride Monohydrate

After the synthesis of tirofiban hydrochloride monohydrate, the product is typically purified to remove any impurities that may have been introduced during the synthesis process.

There are several ways to purify tirofiban hydrochloride monohydrate, including crystallization, chromatography, and recrystallization.

Crystallization is a common method used to purify tirofiban hydrochloride monohydrate.

In this process, the drug is dissolved in a solvent and allowed to crystallize.

The crystals are then collected and dried to produce a pure sample of the drug.

Chromatography is another method used to purify tirofiban hydrochloride monohydrate.

In this process, the drug is passed through a column packed with a solid material, such as silica gel.

The drug molecules are separated based on their size and chemical properties, and the pure product is collected and further purified.

Formulation of Tirofiban Hydrochloride Monohydrate

After the purification of tirofiban hydrochloride monohydrate, the final product is typically formulated into a dosage form suitable for clinical use.

The formulation process involves the addition of excipients, such as diluents, lubricants, and preservatives, to produce a powder or tablet that can be administered to patients.

The formulation process is critical to the efficacy and safety of the drug.

The excipients used in the formulation process must be compatible with the drug and must not interfere with its pharmacological properties.

The formulation process must also be optimized to ensure that the dosage form is stable and can be manufactured consistently.

Quality Control of Tirofiban Hydrochloride Monohydrate

The production of tirofiban hydrochloride monohydrate is subject to strict quality control standards to ensure that the final product meets the requisite purity and potency requirements.

Quality control tests are typically performed at several stages of the production process, including synthesis, purification, and formulation.

The quality control tests performed on tirofiban hydrochloride monohydrate include chemical tests, physical tests, and biological tests.

Chemical tests assess the purity of the drug by measuring its physical properties, such as melting point and solubility.

Physical tests assess the stability and consistency of the drug, while biological tests assess its pharmacological properties.

Conclusion

The production process of tirofiban hydrochloride monohydrate involves several steps, including synthesis, purification, and formulation.

The quality of the final product is critical to its efficacy and safety,