-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

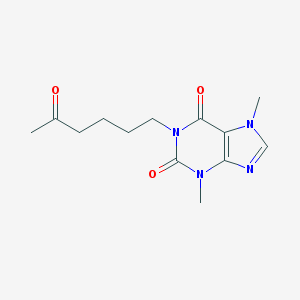

6-Bromo-2-chloro-8-cyclopentyl-5-methylpyrido[2,3-d]pyrimidin-7(8H)-one, also known as CC5013, is a synthetic compound that has been used in various applications within the chemical industry.

The compound is structurally classified as a heterocyclic organic compound and is commonly used as a building block for the synthesis of other organic molecules.

The synthesis of CC5013 involves several steps, which can be broadly classified into three categories: traditional synthesis methods, modern synthesis methods, and industrial synthesis methods.

Traditional synthesis methods involve the use of conventional chemical reactions and techniques that have been used for several decades.

These methods are often less efficient and more time-consuming compared to modern synthesis methods, but they can still be effective for small-scale production.

Some of the traditional synthesis methods used for the synthesis of CC5013 include:

- Grignard reaction: This reaction involves the treatment of an alkyl halide with magnesium metal to form a Grignard reagent.

The Grignard reagent is then treated with a carboxylic acid to form a new organic compound. - Reductive alkylation: This reaction involves the reduction of a halogenated alkane with a reducing agent, such as lithium aluminum hydride (LiAlH4), to form a new organic compound.

- Nucleophilic substitution: This reaction involves the replacement of a functional group in a molecule with a nucleophile, such as an amine.

Modern synthesis methods involve the use of newer chemical reactions and techniques that have been developed over the past few decades.

These methods are often more efficient and less time-consuming compared to traditional methods, and they are widely used in the production of CC5013.

Some of the modern synthesis methods used for the synthesis of CC5013 include:

- Pd/C-mediated coupling: This reaction involves the treatment of an aryl halide with a palladium catalyst and carbon to form a new organic compound.

- Suzuki coupling: This reaction involves the treatment of an aryl boronic acid with a phenylboronic acid in the presence of a palladium catalyst to form a new organic compound.

- Stille coupling: This reaction involves the treatment of an aryl halide with a metal halide and a phosphine ligand to form a new organic compound.

Industrial synthesis methods involve the use of large-scale production techniques that are used to synthesize large quantities of CC5013.

These methods are often more efficient and less costly compared to traditional and modern synthesis methods.

Some of the industrial synthesis methods used for the synthesis of CC5013 include:

- High-pressure hydrolysis: This reaction involves the treatment of an alkyl halide with water under high pressure to form a new organic compound.

- Enzymatic hydrolysis: This reaction involves the treatment of an alkyl halide with an enzyme, such as a lipase, to form a new organic compound.

- Hydrogenation: This reaction involves the treatment of a halogenated organic compound with hydrogen gas to remove the halogen and form a new organic compound.

In conclusion, the synthesis of CC5013 involves several steps, which can be broadly classified into three categories: traditional synthesis methods, modern synthesis methods, and industrial synthesis methods.

Each method has its own advantages and disadvantages, and the choice of method depends on the specific requirements of the application.