-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

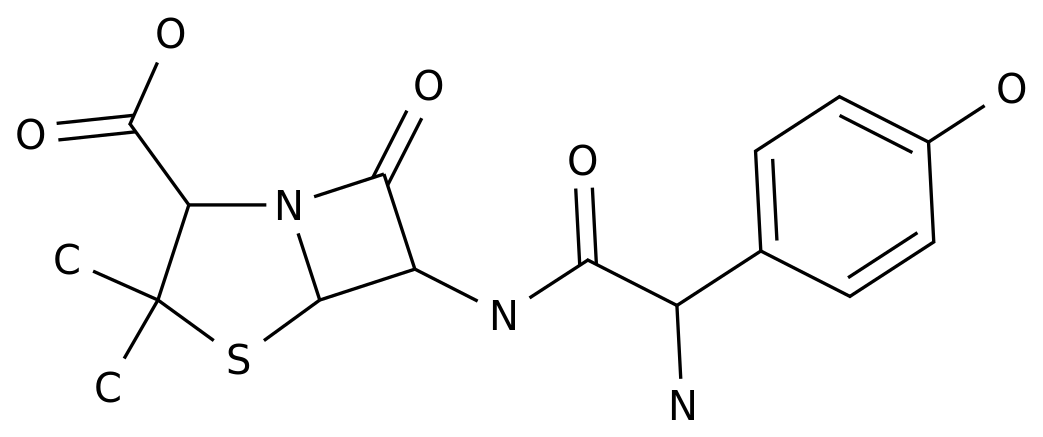

Minocycline hydrochloride is an antibiotic drug that is commonly used to treat a wide range of bacterial infections.

It is a semisynthetic derivative of tetracycline, and it has a broad spectrum of activity against Gram-positive and some Gram-negative bacteria.

The demand for minocycline hydrochloride has been steadily increasing in recent years, and as a result, there has been a significant amount of research into the synthetic routes for this compound.

The traditional synthetic route for minocycline hydrochloride involves a multi-step process that involves the synthesis of the basic structure of the compound, followed by a series of chemical modifications to produce the final product.

This process is complex and can be costly, which has led to the development of alternative synthetic routes.

One of the most promising alternative synthetic routes for minocycline hydrochloride is the use of biotechnology.

This method involves the use of microorganisms to produce the compound.

The process begins with the isolation of a strain of bacteria that is capable of producing the compound.

The bacteria are then genetically modified to increase their production of the compound, and they are grown in a fermenter.

The compound is then extracted from the fermenter and purified to produce the final product.

This method has several advantages over the traditional synthetic route.

Firstly, it is more environmentally friendly, as it does not involve the use of harsh chemicals.

Secondly, it is more cost-effective, as it eliminates the need for multiple chemical reactions and purification steps.

Finally, it is more scalable, as the process can be easily adapted to produce large quantities of the compound.

Another alternative synthetic route for minocycline hydrochloride is the use of green chemistry principles.

This method involves the use of more environmentally friendly reagents and solvents, as well as the optimization of reaction conditions to reduce waste and increase the efficiency of the reaction.

This approach has been successful in reducing the waste and toxicity associated with traditional synthesis methods, and it has also led to the development of new synthetic routes that are more efficient and cost-effective.

In conclusion, the synthetic routes of minocycline hydrochloride have undergone significant changes in recent years, with the development of alternative methods such as biotechnology and green chemistry.

These methods offer several advantages over the traditional synthetic route, including environmental friendliness, cost-effectiveness, and scalability.

As the demand for minocycline hydrochloride continues to increase, it is likely that these alternative methods will become increasingly important in the production of this important antibiotic drug.