-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Synthetic routes of N-Ethyl-3-nitrobenzenesulfonamide: An Overview in Chemical Industry

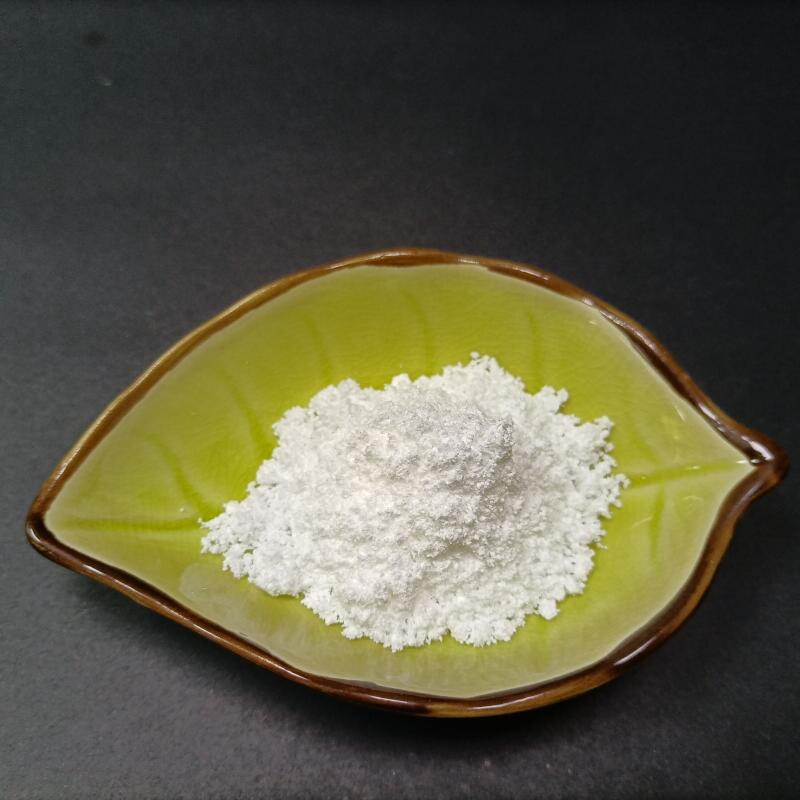

N-Ethyl-3-nitrobenzenesulfonamide, commonly known as NENS, is an important organic compound that is widely used in various industrial applications.

This compound is often synthesized through different chemical routes, which vary in terms of their complexity, cost, and efficiency.

In this article, we will discuss some of the most commonly used synthetic routes for N-Ethyl-3-nitrobenzenesulfonamide, and their significance in the chemical industry.

Route 1: The classic route

The most classic route for synthesizing N-Ethyl-3-nitrobenzenesulfonamide involves the reaction of ethyl iodide with 3-nitrobenzene in the presence of a strong acid catalyst, such as sulfuric acid or phosphoric acid.

This route involves the following steps:

- Reaction of ethyl iodide with 3-nitrobenzene in the presence of a strong acid catalyst to form the nitro compound.

- Treatment of the nitro compound with a base, such as sodium hydroxide, to convert it into the corresponding sulfonamide.

- Purification of the sulfonamide product to remove any remaining impurities.

This classic route is simple and easy to implement, and is still used in some laboratories and small-scale operations.

However, it has been largely replaced by more efficient and cost-effective methods.

Route 2: The Ullmann condensation route

The Ullmann condensation route is a widely used method for synthesizing N-Ethyl-3-nitrobenzenesulfonamide.

This route involves the following steps:

- Reaction of sodium ethylate with 3-nitrobenzene in the presence of a condensation catalyst, such as zinc chloride or aluminum chloride, to form the nitro compound.

- Treatment of the nitro compound with ethylamine in the presence of a solvent, such as acetone or dichloromethane, to form the Ullmann complex.

- Treatment of the Ullmann complex with a strong acid, such as hydrochloric acid or sulfuric acid, to form the sulfonamide.

- Purification of the sulfonamide product to remove any remaining impurities.

The Ullmann condensation route is more efficient and cost-effective than the classic route, as it reduces the number of steps required for synthesizing N-Ethyl-3-nitrobenzenesulfonamide.

This method is widely used in the chemical industry, particularly in large-scale operations.

Route 3: The Stille reaction route

The Stille reaction route is another commonly used method for synthesizing N-Ethyl-3-nitrobenzenesulfonamide.

This route involves the following steps:

- Reaction of 3-nitrobenzene with cesium carbonate and ethyl iodide in the presence of a palladium catalyst, such as tetrakis(triphenylphosphine)palladium(0), to form the nitro compound.

- Treatment of the nitro compound with a base, such as sodium hydroxide, to form the sulfonamide.

- Purification of the sulfonamide product to remove any remaining impurities.

The Stille reaction route is highly efficient and can be used to synthesize a wide range of organic compounds.

This method is gaining popularity in the chemical industry, particularly in research and development applications.

Conclusion

In conclusion, N-Ethyl-3-nitrobenzenesulfonamide is an important