-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Niludipine is a pharmaceutical drug that is used to treat hypertension and other cardiovascular diseases.

It belongs to the class of drugs known as calcium channel blockers, which work by relaxing the smooth muscle in the walls of blood vessels, causing them to widen and allowing blood to flow more easily.

Niludipine is synthesized through several synthetic routes, which can be broadly classified into three categories: classical synthesis, total synthesis, and semi-synthesis.

Classical Synthesis of Niludipine

The classical synthesis of niludipine involves a series of chemical reactions that convert a raw material into the final product.

This method involves the use of readily available starting materials and typical laboratory equipment, making it a cost-effective and efficient way to synthesize the drug.

One of the most common methods of classical synthesis of niludipine involves the reaction of diethylsertibenzamide with chloral hydrate in the presence of an acid catalyst.

This reaction leads to the formation of a intermediate, which is then converted into niludipine through further chemical reactions.

Total Synthesis of Niludipine

The total synthesis of niludipine involves the use of advanced chemical methods and techniques to synthesize the drug from its constituent parts.

This method is more complex and time-consuming than classical synthesis, but it allows for greater control over the synthesis process and the ability to modify the structure of the drug to improve its properties.

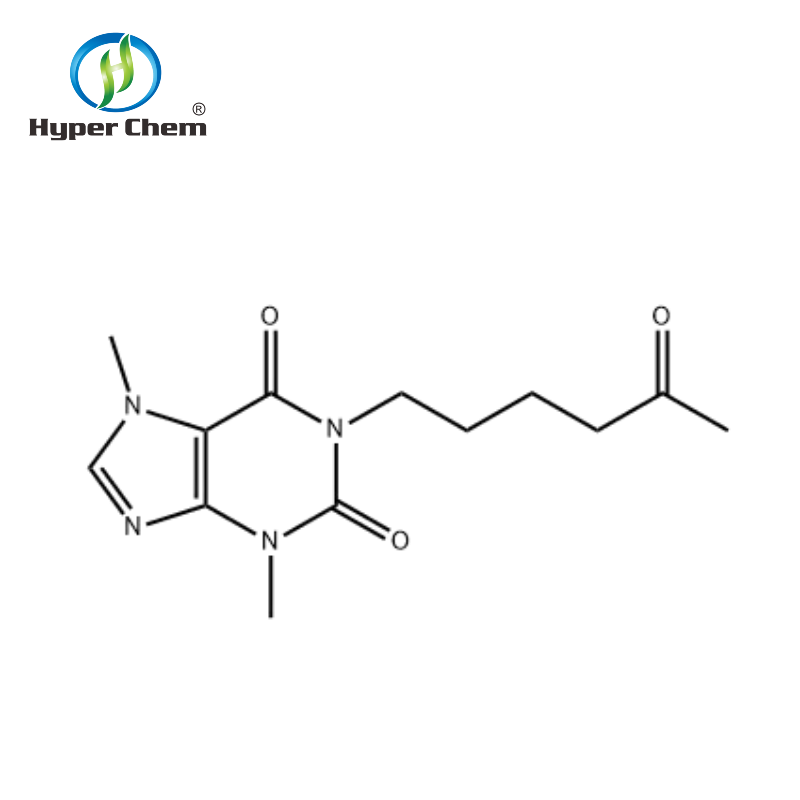

One of the total synthesis methods of niludipine involves the synthesis of the cycloheximide ring followed by the introduction of the phthalimide moiety.

This method involves several steps, including the condensation of β-keto esters and amino acids, followed by cyclization and functionalization steps.

Semi-Synthesis of Niludipine

The semi-synthesis of niludipine involves the synthesis of the drug using a combination of classical and total synthesis methods.

This method allows for the use of readily available starting materials and advanced synthetic techniques to produce the final product.

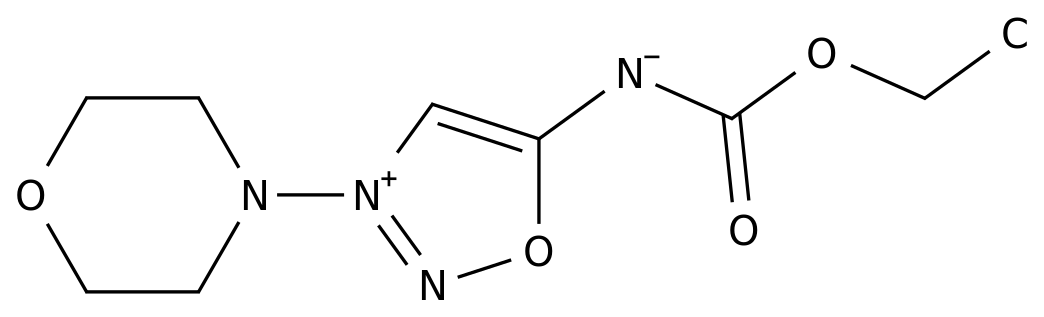

One of the semi-synthesis methods of niludipine involves the synthesis of the phthalimide moiety through the reaction of anhydrous hydrochloric acid with methyl 2-(4-chlorophenyl)-4,4,5,5-tetraacetamido-1,3,4-oxadiazidate.

This intermediate is then reacted with diethylsertibenzamide to form niludipine.

Challenges in Synthesizing Niludipine

One of the main challenges in synthesizing niludipine is the need for strict control over the synthesis process to ensure that the final product is of high purity and potency.

This requires the use of advanced equipment and techniques, which can increase the cost and complexity of the synthesis process.

Another challenge is the need for the use of expensive and rare starting materials, which can make the synthesis of niludipine economically unfeasible.

In addition, the synthesis of niludipine requires a high level of expertise and knowledge of advanced chemical techniques, which can make it difficult for researchers without specialized training to synthesize the drug.

Conclusion

In conclusion, niludipine can be synthesized through several synthetic routes, including classical, total, and semi-synthesis methods.

Each method has its own advantages and challenges, and the choice of synthesis route depends on factors such as the availability of starting materials, the desired purity and potency of the final product, and the expertise of the synthesizer.

The synthesis of niludipine is a complex process that requires a high level of expertise and knowledge of advanced chemical techniques, and it is an important area of research in the pharmaceutical industry.