-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

- Cosmetic Ingredient

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

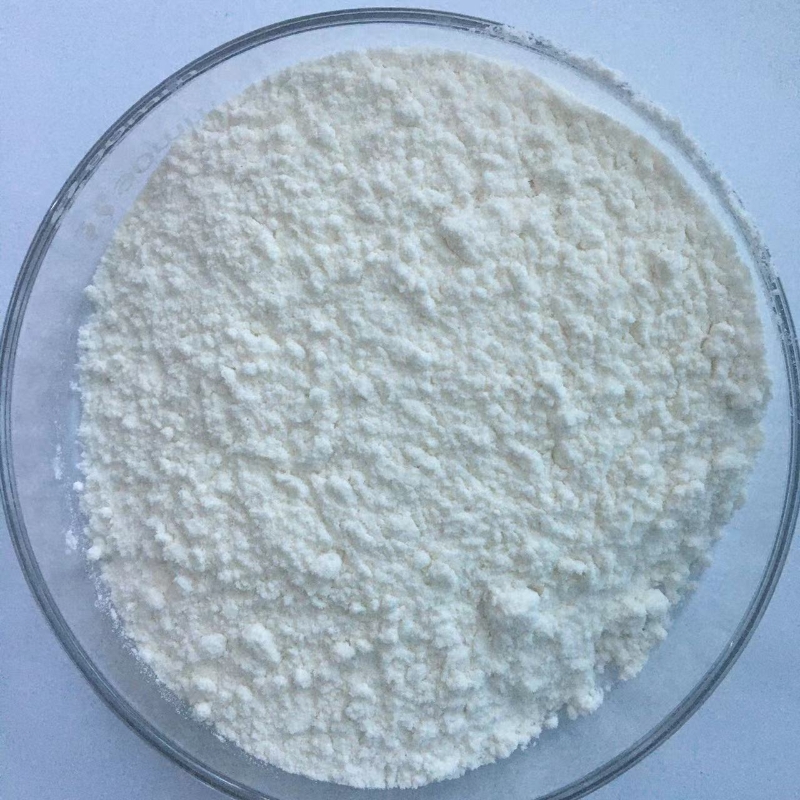

(2β,4α,15α)-15-Hydroxy-2-[[2-O-(3-methyl-1-oxobutyl)-3,4-di-O-sulfo-β-D-glucopyranosyl]oxy]-19-norkaur-16-en-18-oic acid, commonly referred to as 15-Hydroxy-19-norkaur-16-en-18-oic acid or simply 15-Hydroxykaur-16-en-18-oic acid, is a naturally occurring compound found in the bark of the cinnamon tree.

It has been widely studied for its potential health benefits, including its ability to lower blood sugar levels and treat type 2 diabetes.

In recent years, 15-Hydroxykaur-16-en-18-oic acid has become an increasingly popular ingredient in dietary supplements and functional foods.

This has led to an increase in demand for the compound, which has in turn led to an increase in the number of manufacturers producing it.

The production of 15-Hydroxykaur-16-en-18-oic acid involves several steps, including isolation from the cinnamon bark, purification, and synthesis.

The purification process typically involves the use of chemical reactions to remove impurities, while the synthesis process involves the use of chemical reactions to create the compound from starting materials.

One of the key challenges in the production of 15-Hydroxykaur-16-en-18-oic acid is the high cost of production.

The purification and synthesis processes can be expensive and time-consuming, which can make the final product cost-prohibitive for many consumers.

Additionally, the supply of the compound can be inconsistent, leading to shortages and difficulties for manufacturers.

Despite these challenges, the demand for 15-Hydroxykaur-16-en-18-oic acid is expected to continue to grow as more studies are conducted on its potential health benefits.

As a result, manufacturers and researchers are actively seeking ways to improve the efficiency and cost-effectiveness of the production process.

One potential solution is the use of biotechnology to produce 15-Hydroxykaur-16-en-18-oic acid.

By using genetically modified microorganisms, it may be possible to synthesize the compound more quickly and at a lower cost than traditional methods.

This approach could also lead to a more consistent supply of the compound, as it would not be subject to the same supply chain issues as naturally occurring compounds.

Another potential solution is the use of alternative starting materials.

By using different plant-based compounds or synthetic chemicals as starting materials, it may be possible to synthesize 15-Hydroxykaur-16-en-18-oic acid more efficiently and at a lower cost.

In conclusion, the production of 15-Hydroxykaur-16-en-18-oic acid is a complex and challenging process that is subject to a number of factors, including cost, supply, and purity.

Despite these challenges, the demand for the compound is expected to continue to grow as more studies are conducted on its potential health benefits.

As a result, manufacturers and researchers are actively seeking ways to improve the production process and make the compound more accessible to consumers.

Upstream and Downstream Products

The production of 15-Hydroxykaur-16-en-18-oic acid involves several upstream and downstream products.

Upstream products include the starting materials used in the production process, such as cinnamon bark, chemical reagents, and microorganisms.

These products must be of high quality and purity to ensure the final product is of the same quality and purity.

Downstream products include the final product, which is used in dietary supplements and functional foods.

Downstream products also include any intermediate products that are produced during the purification and synthesis process.

In addition