-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

In the chemical industry, an important aspect to consider is the concept of upstream and downstream products.

Upstream products are the raw materials that are used to make the final product, while downstream products are the final products that are made from the raw materials.

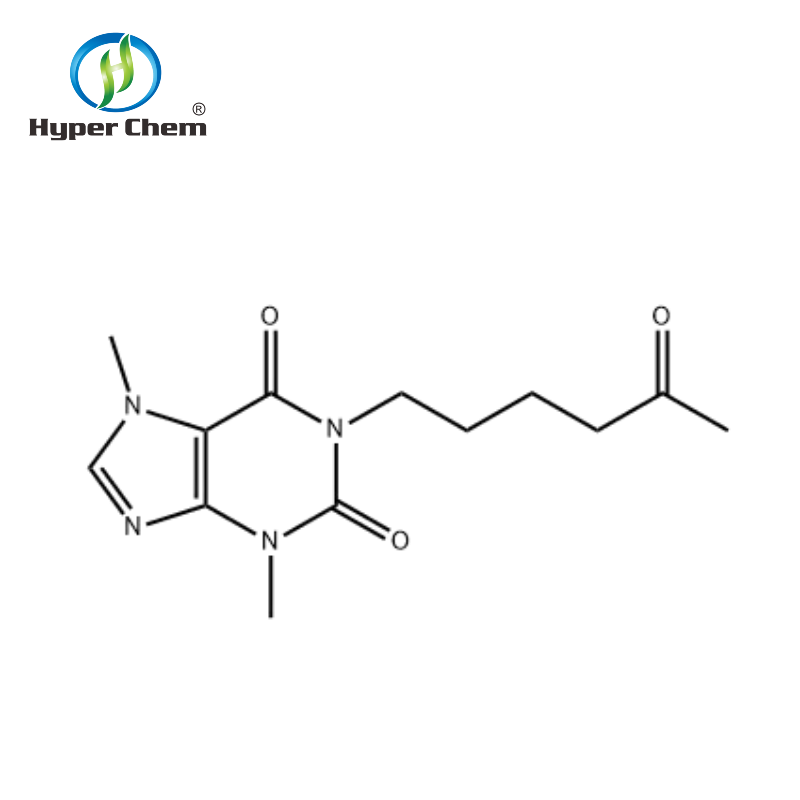

In the context of niludipine, a calcium channel blocker drug used to treat hypertension and angina pectoris, the upstream and downstream products are the raw materials and intermediates used to manufacture the drug, as well as the drug itself.

The upstream products for niludipine include the raw materials used in its manufacturing process.

The main raw material for niludipine is diphenylmethane, which is synthesized from benzene and phenylene oxide.

Other raw materials include ethanol, sodium hydroxide, hydrochloric acid, and water.

The diphenylmethane is then converted into niludipine through a series of chemical reactions, including nitration, hydrolysis, and cyclization.

The downstream products for niludipine include the final product, which is the drug itself, as well as any intermediates used in its manufacturing process.

The intermediates include the nitrate, hydrochloride, and base forms of niludipine, which are used in the final stages of the manufacturing process to produce the final drug.

The manufacturing process for niludipine involves several steps, including purification and formulation.

The final product is tested for purity and quality, and is then packaged in the appropriate form, such as tablets or capsules.

Downstream processes may also include further processing to create different forms of the drug, such as extended-release formulations or liquid preparations.

It is important to note that the upstream and downstream products of niludipine are highly regulated by government agencies such as the FDA.

This is done to ensure that the drugs are safe and effective for use by the general public.

The manufacturing process for the drug must also comply with strict quality standards to ensure that the final product is of the highest quality.

In conclusion, the upstream and downstream products of niludipine are an integral part of the drug manufacturing process.

The raw materials used in its manufacturing process include diphenylmethane and other chemicals, while the downstream products include the final drug and any intermediates used in its manufacturing process.

The manufacturing process for niludipine is a complex process that involves several steps, and is highly regulated by government agencies to ensure the safety and efficacy of the final product.

This highlights the importance of the upstream and downstream products in the chemical industry.