-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Sodium caseinate, a popular milk protein, has a wide range of applications in the chemical industry.

It is used in various cosmetic and pharmaceutical products, food and beverage industries, and in the production of various chemicals.

Sodium caseinate can be derived from skimmed milk through a process known as acid precipitation, followed by neutralization, filtration, and drying.

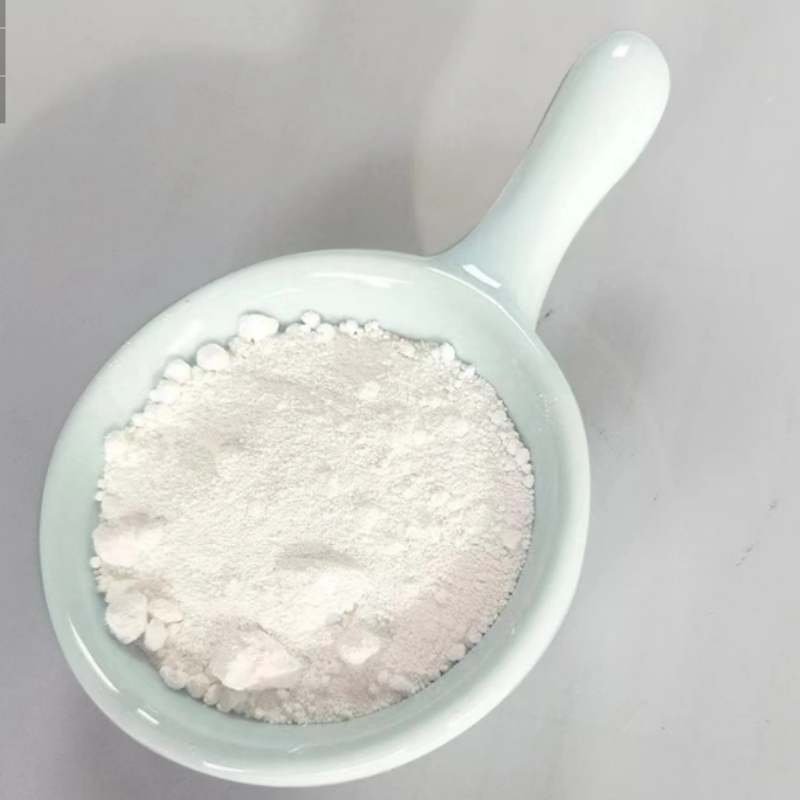

The product obtained is a white to off-white powder that has a milky odor.

The upstream and downstream products of Sodium caseinate are closely related and interdependent.

Upstream Products

The upstream products of Sodium caseinate are the raw materials required for its production.

The main raw material used in the production of Sodium caseinate is skimmed milk.

Other raw materials include water, acid, and a neutralizing agent such as sodium hydroxide.

The acid used can be hydrochloric acid, sulfuric acid, or lactic acid.

The choice of acid depends on the desired properties of the final product.

Downstream Products

The downstream products of Sodium caseinate are the various end products that can be derived from it.

Sodium caseinate is widely used in the food and beverage industry as an additive in various products such as cheese, yogurt, ice cream, and bakery products.

It has emulsifying, thickening, and stabilizing properties that make it ideal for use in these products.

In the cosmetic industry, Sodium caseinate is used as an ingredient in various creams, lotions, and gels.

It is also used in the pharmaceutical industry as an excipient in the formulation of tablets and capsules.

The production of Sodium caseinate also results in the production of other chemicals such as L-glutamic acid and L-alanine.

These products can be further processed to produce various other chemicals such as amino acids, peptides, and other food additives.

The production process of Sodium caseinate involves several steps, including acid precipitation, neutralization, filtration, and drying.

In the acid precipitation step, the skimmed milk is mixed with acid, and the casein molecules are precipitated.

The resulting mixture is then neutralized with a base such as sodium hydroxide to produce a jelly-like mass.

The mass is then filtered to remove any impurities and dried to obtain a powder.

The upstream and downstream products of Sodium caseinate are closely related, and the choice of raw materials and the production process can significantly impact the quality and properties of the final product.

For instance, the choice of acid used in the production process can affect the properties of the final product.

Hydrochloric acid produces a powder that is more soluble in water, while lactic acid produces a powder that has better stability in aqueous solutions.

The neutralizing agent used can also affect the properties of the final product.

Sodium hydroxide produces a product with a higher pH, which is more stable in aqueous solutions.

The production of Sodium caseinate also has a significant impact on the environment.

The use of skimmed milk as a raw material requires the production of large quantities of milk, which can have a significant impact on the environment.

The production process also generates waste products such as whey and acid that can have a negative impact on the environment if not properly disposed of.

In conclusion, Sodium caseinate is a widely used product in the chemical industry, with a variety of upstream and downstream products.

Its production process involves several steps, and the choice of raw materials and production process can significantly impact the quality and properties of the final product.

The production of Sodium caseinate also has a significant impact on the environment, and proper waste management practices should be implemented to minimize its negative impact.